SMT Assembly Line Machine Dip Wave Soldering Machine Automatic Soldering Machine

Product introduction:

● PLC and touchscreen controlling system which can save more than 50 sets parameters. User-frienly

interface is easy to be operated,temperature can be set/saved/modified in touchscreen.

● The high quality sprayer provides perfect atomization performance of the flux.It is driven by stepper motor and rail / slider, moving speed set on touchscreen, stepper driver and PLC control system make a smooth and low noisy movement.

● Forced air convection preheat zone creates enough uniform heat for the PCB.Specially designed preheating system makes maintenance easier,motor and blower can be dismantled easily from bottom,heater can be move out from rear side like drawer.

● Adopt cast iron heater for the solder pot, its mounted outside of the solder pot. This new assembling way prolongs the lifetime of the solder pot.

● Dual wave solder pot. Both wave heights are controlled invidually by transducer. Changing the wave height via adjusting the frequency of wave motor's power supply in touchscreen.

● Solder pot is made of Ti material, 100% capable for the lead-free solder.

● Customer can set on and off time of machine with weekly timer.

● Light&Sound alarm for overheating and emergency stop.

● Ti finger conveyor system, be able to form an in-line through-hole soldering line.

● Customer can choose "L" finger for pallet, or dual hook finger for pcb.

● N2 optional for the solder pot.

Details:

![]()

ln-loading system

Which can connect with the insertion conveyor directly, the sensor atbottom for counting and spray fluxer on/off; with ruler and and needle forinstruction of width.

![]()

Fluxing system

Air supply to spray flux system, all the air flow pressure is adjustable byflow pressure meter.

![]()

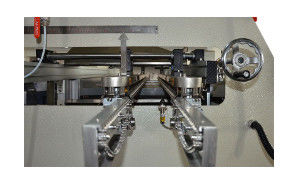

Movement of fluxing system

The high quality sprayer driven by stepper motor and rail/ slider, movingspeed set on touchscreen, stepper driver and PLC control system make asmooth and low noisy movement. Compare with traditional air cylinderdrive, the moving speed can be set in touchscreen and moving speed willnot be influented by air pressure like air cylinder.

FAQ:

Q: How do you guarantee the quality of your sales?

A: We ensure the quality of our products through rigorous testing before delivery. Every set of machines undergoes thorough testing to ensure excellent performance and reliability.

Q: How is the training process?

A: After purchasing our machines, your engineers can visit our company for training. Alternatively, we provide comprehensive training materials, including training videos and user manuals, which make it easy to learn and operate the machines. The user manual will be provided along with the machine.

Q: Can I have my logo on the product?

A: Yes, we offer customized logo services free of charge. Please let us know your requirements, and we will ensure your logo is incorporated onto the product.

Q: Are the machines difficult to use?

A: No, the machines are designed to be user-friendly. Previous clients have found that it takes a maximum of two days to learn how to operate the machines effectively.

| Company | Shenzhen Honreal Technology CO.,Ltd. |

| Address | No15,Shangnan Hongma Road, Shajing Street, Baoan District, Shenzhen, Guangdong Province, China |

| Tel | +86 755 2302 0279 |

| Fax | +86 755 2330 6782 |

| Zip code | 518125 |

| Skype/Whatsapp/Wechat | +8613715227009 |

| Email: | Monica@szhonreal.com |